Blast-proof security

Explosion resistance

A security shutter’s resistance to explosions is classified in compliance with regulations EN 13124-1:2001 and EN 13124-2:2004. The first one refers to the elements tested against blast waves generated through an impact tube, whilst the second refers to the tests conducted against shock waves produced outdoors.

The multiple tests and certifications our products have undergone guarantee their resistance to explosions. According to the regulations in force, there are three kinds of tests to determine the resistance to explosions: 1) when the explosive charge is high, for instance in the case of a car bomb; 2) when the explosive charge is low but is situated at a short distance, for instance in the case of a backpack bomb; or 3) in cases of explosions of low pressure but long duration like a petrochemical accident.

To determine the destructive power of the explosion, the distance between the source of the explosion and the element must be taken into consideration, as well as the mass of the explosive charge and the duration of the pressure exerted by the explosion. Based on the interaction between these three factors, the three scenarios described above take place. The effects are tested in outdoor tests to determine the resistance of the different architectural elements.

The classification from lower to higher resistance for tests outdoors in accordance with regulation EN 13123-2:2004 goes from EXR1 to EXR5:

| WINDOWS, DOORS AND SHUTTERS | MASS | DISTANCE |

|---|---|---|

| EXR1 | 3 kg | 5,0 m |

| EXR2 | 3 kg | 3,0 m |

| EXR3 | 12 kg | 5,0 m |

| EXR4 | 12 kg | 4,0 m |

| EXR5 | 20 kg | 4,0 m |

In the case of the classification when subject to explosion test through shockwaves using an impact tube, levels go from EPR1 to EPR4, as follows:

| Model | MAXIMUM PRESSURE (bar)* | SPECIFIC POSITIVE IMPULSE (bar-ms) |

|---|---|---|

| EPR1 | 0,5 | 3,7 m |

| EPR2 | 1,00 | 9,0 m |

| EPR3 | 1,50 | 15,0 m |

| EPR4 | 2,00 | 22,0 m |

*The duration of the positive phase (t+) must not be less than 20 ms.

As applied to bulletproof tests, suffix S or NS is added to determine whether there are (or not) splinters on the security area of the shutter.

Protection against explosions

Armoured products against explosions

Our ANTI-EXPLOSION armored product systems offer different levels of security and the extraordinary resistance of our doors, shutters and curtains made of high-resistance hardened aluminum guarantee maximum certified protection.

All models are equipped with automation and can be integrated into your home automation so that in a few seconds the home is protected.

Explosion resistance

Any explosion generates a blast wave that creates a reflected pressure (or maximum peak) when encountering an obstacle. This peak is taken as reference by the different regulations.

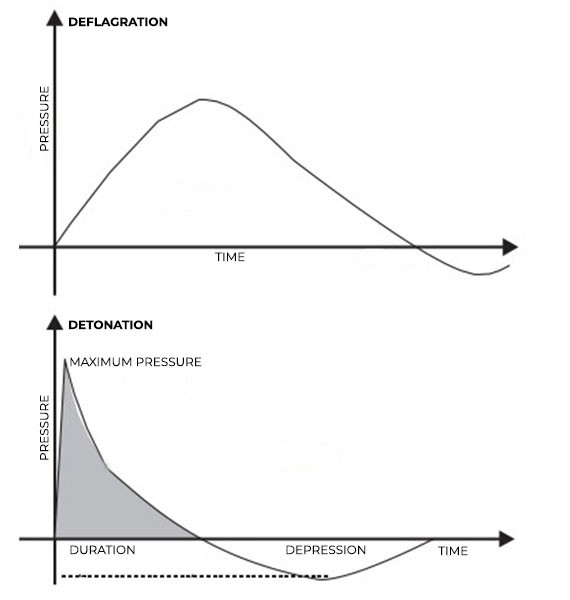

There are two types of explosions: deflagration (an explosion producing a lower pressure but for a longer period of time) and detonation (this type of explosion produces a higher pressure but for a shorter period of time).

A typical deflagration is produced during an industrial explosion, were the duration of the pressure is long but not extremely high, whereas a detonation can be caused by a car bomb that will produce an extremely high pressure that will not last long and quickly turno into a negative pressure (or depression).

The DIAMOND BL X-TREME BLAST and the BL X-TREME MAX are the world’s only blast-resistant security shutters. They are EXR5 certified in accordance with EN-UNE 13123-2:2004, after overcoming all required tests in compliance with this regulation. The coiling doors can support up to 20 kgs of TNT located 4 metres away from the element.

Two types of tests

Standard EN 13123 consists of two different types of tests: EN 13123/124-1 and EN 13123/124-2.

EN 13123/124-1 tests deflagration in shock tube and applies to doors, windows and closings. The class of resistance is determined by a number that goes from 1 to 4 depending on the reflected pressure and for a duration of at least 20 miliseconds. The results produce a classification that goes from EPR1 (reflected pressure of 0,5 bar) to EPR4 (2 bar).

Security elements certified to this test are usually used in premises were industrial explosions may occur (such as oil refineries or petrochemical plants).

EN 13123/124-2 tests detonation outdoors. Also applied to doors, windows and closings, the test’s classification goes from EXR1 to EXR5 but measures the TNT charge (in kilograms) and the distance from the explosion. Class EXR1 corresponds to an element that supports up to 3 kg of TNT situated 5 metres away, while class EXR5 elements can support up to 20 kg of TNT located 4 metres away.

Elements undergoing this test are usually required for buildings that are likely to suffer terrorist attacks (such as embassies or international organization buildings)